Capabilities

Blue Ridge Pressure Castings has invested in the equipment needed to ensure our customers receive world class quality aluminum die cast parts and components with on time delivery.

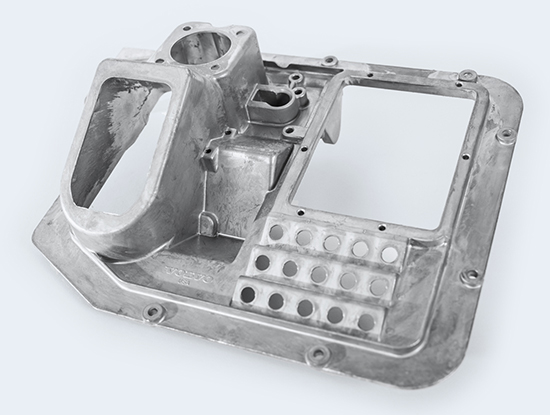

Using modern die casting cells capable of 600 to 1800 tons locking force, we produce parts up to 50 pounds. These include heavy truck transmission covers and large diesel engine valve covers.

Our CNC machining cells are integrated with our casting capabilities to provide finished solutions to our clients.

Engineering and Design

Blue Ridge provides superior engineering and prototyping capabilities. Our staff works with our clients to optimize component designs for cost, quality and functionality. We have a command of the latest in tooling and alloy technologies which allow us to provide our clients with value added solutions to meet their design needs. Using the completed part design, we then develop a tool design optimized to deliver high quality and cost competitive parts while keeping maintenance requirements to a minimum.

In addition, we have developed real value prototyping strategies that meet cost and time constraints and generate valuable data needed for validating component design.

Quality and Delivery

Quality and Delivery

Blue Ridge retains ISO 14001 and IATF 16949 certifications. More importantly, our staff understands that customers require on-time delivery AND outstanding quality in order to keep their plants running smoothly and cost effectively. Top quality starts with the raw material. We have developed a reliable aluminum supply base which supplies material which meets or exceeds BR and ASTM B85 specifications.

We understand the potential issues associated with high pressure die casting. We consider it a matter of pride that we protect our customers from any issues by catching and correcting them in-house with no impact on delivery schedules. Our lab follows a rigorous quality regime utilizing the following equipment:

- State of the Art CMM’s (3)

- Mahr surface profile measurement

- Mitutoyo Profile Projector

- X-Ray

- Spectrometer

Extensive use of robotics stabilizes process variables and effectively reduces labor costs. Medium and higher volume production utilizes fully automated cast and trim fully operations.

Blue Ridge combines excellent tools with lean manufacturing to deliver cost effective die cast aluminum parts that meet the industry’s highest standards. With our expertise and equipment, we work from the earliest design stages through production processes to deliver quality products which meet or exceed customer standards while delivering to plan.