Engine Components

Blue Ridge Pressure Castings specializes in manufacturing quality engine components for all types of vehicles ranging from heavy trucks, all terrain vehicles, automobiles and beyond.

If your company needs a custom application, Blue Ridge has the engineering expertise and full machining, finishing and quality certification services to get the job done.

The two most common aluminum die castings Blue Ridge makes are valve covers and engine control covers.

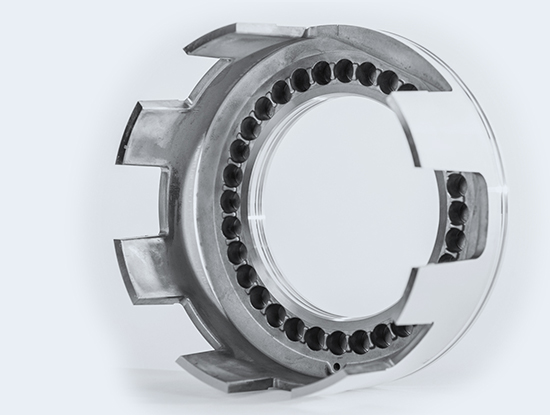

Engine Control Covers.

The ECU is contained within an engine control cover or housing usually aluminum die casted. The die casting allows for all the electronics, connectors and other components necessary for the engine control unit to fit within the engine properly.

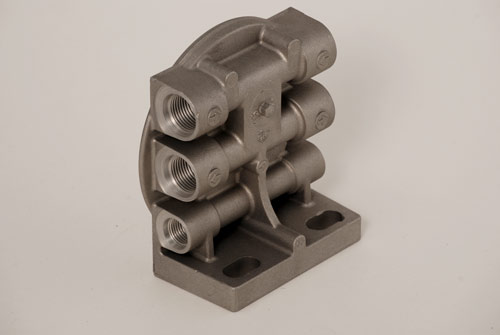

Valve Covers

Valve covers are unique for different models of vehicle and have different mountings and accessory holes depending on the application.

Every vehicle includes engine parts which are responsible for the overall motion of the vehicle itself. From these parts, the valves are the ones responsible to let the air and fuel in and to let the exhaust out. Both the intake and exhaust valves open at the proper time and are closed during compression and combustion so that the combustion chamber is sealed. A set of valves and the mechanism that opens and closes them is called the valve trains. It consists of rocker arms, valve springs, push rods, lifters and cam if it’s an overhead cam engine. And since the valve trains play a vital part in the whole engine system, it is covered with the valve cover.

As the name implies, the valve cover serves as the covering of the valve trains. This can be removed to adjust the valves. This is often distorted on older cars, because there are valve cover screws that are sometimes over-tightened which causes the valve cover to bend after some time. Underneath the valve cover, oil is dispersed after being pushed up through the pushrods. This keeps the rocker arms lubricated and there are holes located in various places in the engine head so that the oil circulates back down to the oil pan. Because of this, the valve cover should always be oil-tight. But if the valve cover is over tightened and is just made of very thin sheet metal, the valve cover will bend and eventually will be the source of oil leak