Engineering and Design

Our clients, and even our competitors, consult with Blue Ridge regarding the most challenging and cutting edge pressure cast components. To retain our position as a master in our field, we actively participate in engineering and materials studies with major universities as well as NADCA. As a result, we provide our clients with value through advice on:

- Design characteristics

- Integration of features and part reduction

- Alloy selection including latest developments

- Mold design to deliver quality, part reduction, surface quality and reduced machining

- Component characteristics to meet application requirements

We develop methods to meet client needs such as:

- Meeting automotive class-a surface requirements out of the mold and ready for coating or chroming

- Producing optically flat components for laser measuring devices

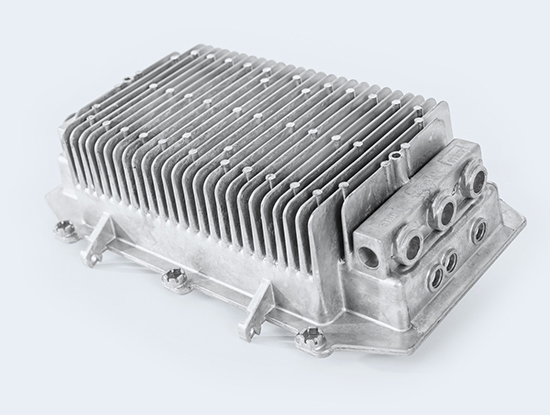

- Sophisticated mold release systems for complex parts such as stators with incorporated fin designs

- Integrated precision cores, such as those found on valve bodies, to eliminate machining

- Integrated bosses and brackets to eliminate part count, reduce costs and improve quality

- Effective heat transfer fins built into structures

Our team enthusiastically pursues complex parts which demand cutting edge solutions. We delve into the details of design, development, tooling and manufacturing to ensure our customers receive consistently top quality parts which meet their technical needs.